#136 October Status Report

October 11, 2018

This is the fifth installment in these articles about the development and construction of the Aerial Tramway for the EnterTRAINment Junction (EJ) layout. This time we’ll look at the passenger stations at the bottom and top of the tramway. The purpose for the station buildings is to provide some degree of protection from the weather for the passenger as they wait for the tram car to arrive and as they get in and out of the car. A secondary purpose, more important for the model, is to conceal the tram’s above-layout-table operating gear, which is in no way to scale compared to the rest of the model.

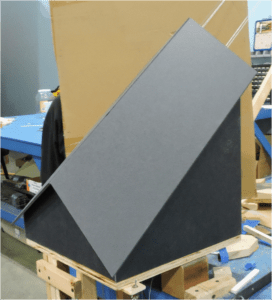

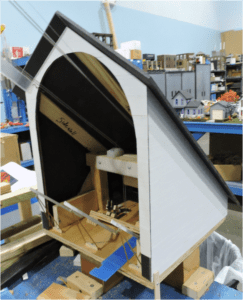

The left picture in Figure 1 (also shown in Article No. 134) shows the cardboard mockup of the lower station; the picture at the right shows its final Gator Board ® structure. In order to allow maintenance access to the tram operating gear, the station building needs to be removable, and it would be best for it to be removable as a single unit, to minimize the difficulty for the maintainers.

|

| Figure 1. Lower Station Mockup and Final Structure |

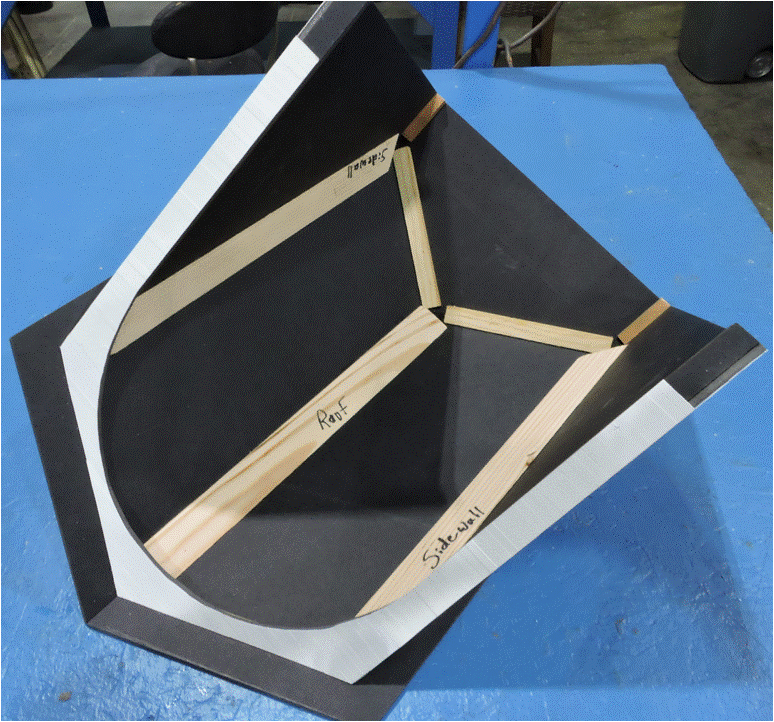

In order for the station building to be removable as a unit, it cannot have a cross-brace across the lower part of the front wall opening. Otherwise the tram track cables would prevent the opening from being lowered over the cables. But, the building needs to be structurally stiff and strong enough to retain its shape during removal and installation. To ensure that it has that needed structural integrity, wooden gussets – cut to match the intersecting angles between the roof and the walls, between the wall panels, and between the two roof panels – were glued across the all of the roof and wall joints (Figure 2). The cardboard mockup came in handy for measuring those intersecting angles in preparation for cutting the gussets to the correct angles. The likely handles for picking up the station would be the roof overhangs on either side to the building, so the gussets in the roof-to-sidewall joints are especially wide.

|

| Figure 2. Station Structural Joint Stiffeners |

The left side of Figure 3 shows the lower station from the right rear. Still to be added are a door in the rear wall and a ticket booth and control station on the right wall. The right side of Figure two shows the beginnings of the plastic siding used on the exterior of the station walls.

|

| Figure 3. Lower Station Bare and with Siding Started |

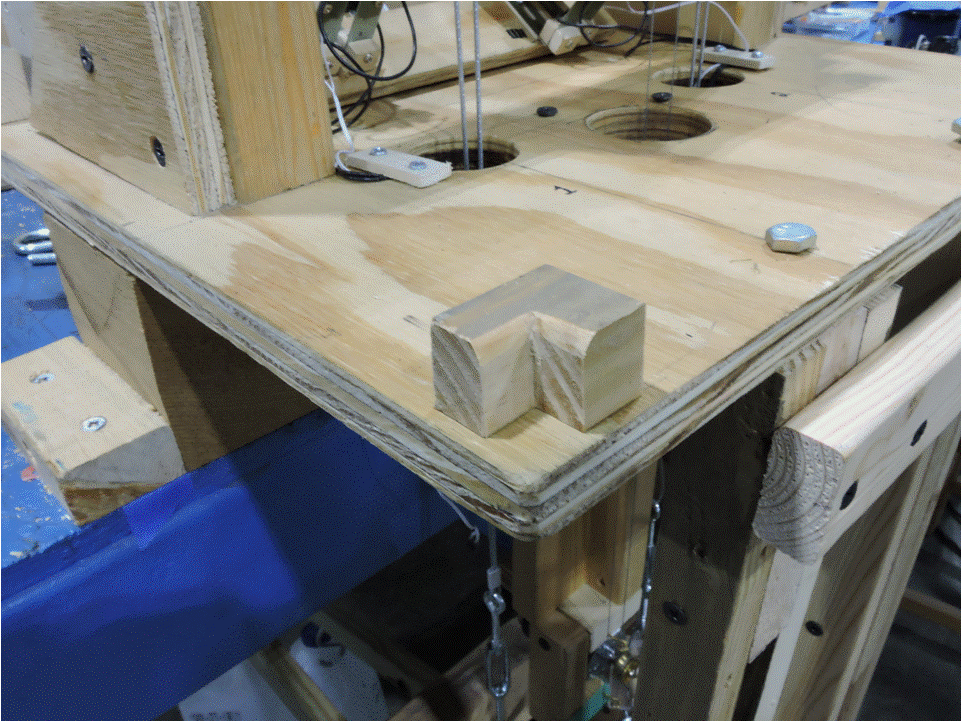

To make installation of the buildings easier and to ensure their correct location, blocks are installed on the corners of the station base-plates to interface with the interior corners of the buildings (Figure 4). The cutout in the block shown in the figure is to make room for the side-to-back-wall “gusset.” Note the chamfers on the cutout to allow some misalignment during installation and to guide the corner into the correct position as the building is being lowered onto the base-plate.

|

| Figure 4. Station Building Locating Block |

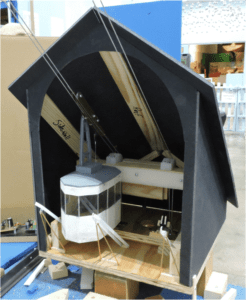

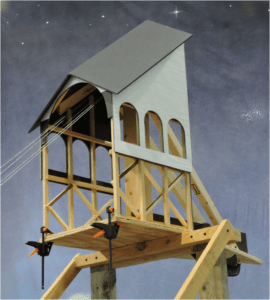

Figure 5 shows the back of the upper station during a test assembly and installation. Note the clamps and tape holding the parts together. A building extension will be added to the back of the station to cover the diagonal braces, which are needed to transfer the tension from the track wires to the station base-plate and from there to the layout shelf on which the station will be located. (The yellow caution tape under the rear of the base-plate is to warn passers-by of the cable that’s used to transfer the load from track cable tension to the base of the tram test fixture. Fortunately, the point on the back of the base-plate is safely above head height where the fixture is located.)

|

| Figure 5. Upper Station Assembly Test |

The left image in Figure 6 shows the front of the upper station during the test assembly. The right image in Figure 6 shows the main part of the station assembled and with the some of the side and front wall siding added. The passenger platforms will be at the height of the bottom of the windowed walls. The building needs to be tall enough to allow the tram car to clear the front edge of the base-plate, and to hide the operating gear at the upper end of the track cables. The needed height is strongly influenced by the angle of track cables. The open framework and large windows for this station were chosen to make it possible to see through the station to the beautifully modeled building which will be located next to it on the layout’s mezzanine-wall shelf. Just like the lower station, this station building needs to be removable to enable maintenance, and it too has the strengthening gussets across the joints between walls and roof panels.

|

| Figure 6. Upper Station Test and Assembled |

As you can see, progress is being made. Next to be done are construction of the upper station extension, the upper station’s sway guides, the passenger platforms inside both stations, and a lot of painting of the stations and the tram cars. After that will come the preparation of the mounting locations on the layout, which will bring a new set of challenges. So, more reports on tram project progress will be forthcoming. Stay tuned.

© 2018 Tom Bartsch

MVGRS Big Train Project Coordinator

Tickets

Tickets Parties

Parties Shop

Shop Directions

Directions